Civil Design

Public Group

Public Group

Active 3 weeks ago

With very different goals and workflows, Civil design and construction have their own set of... View more

Public Group

Thinking outside the sheet

Tagged: stitching tool

-

Thinking outside the sheet

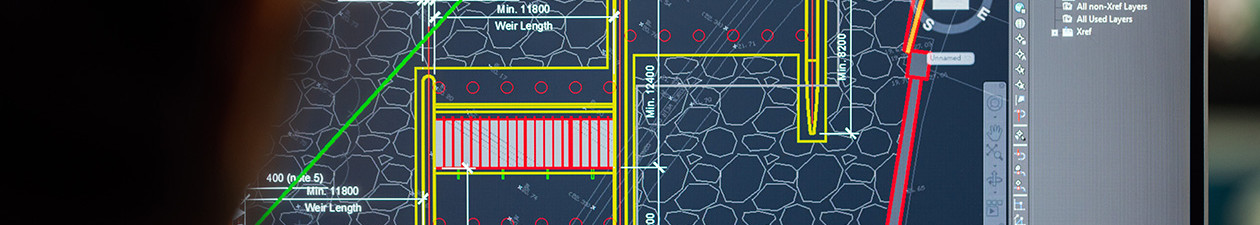

Posted by Jeffrey Collins on December 12, 2021 at 11:43 pmI’m a roadway/highway designer and we’re getting closer to supplying digital 3D models but it’s still going to be some time before that’s the norm wanted/needed for a majority of contractors. In the mean time PDFs have become the new paper and we’re using standard sheet sizes, why??? So we can print hard copies?

If I have a 3 mile long project, at 1”=50’ I’m looking at 12ish sheets just for plan view. That becomes cumbersome to find and “page” through, only to find the information needed spans multiple sheets.

Has any one instead tried creating 1 unknown sheet size (might be 66”x 340”) with the same 1”=50’ scale? Having all the information on one “sheet” only needing to pan around, never worrying about which sheet the information is on?

Wouldn’t this be a good intermediate step from digital plans to digital models? At this point we should be thinking about the limitations of file size not the limitations of a piece of paper, which our plans my never actually be printed on.

Other than, “That’s the way it’s always been done.” Why are we confined to 22×34 or 24×36 sheets of paper when printing to PDFs? Any issues to worry about in Revu?

Would appreciate any and all opinions and insights.

David Cutler replied 2 months, 3 weeks ago 5 Members · 18 Replies -

18 Replies

-

Points: 27,996Rank: UC2 Brainery Advanced Brown Belt I

Welcome to the group @Jeff.Collins

I can definitely feel your pain and agree with the idea of a continuous combined PDF. Here is a blog post/video I did a while back showing how to combine several PDFs just like your asking. https://uchapter2.com/combining-several-pdfs-into-one-pdf-using-bluebeam-revu/?no_frame=1

I know because CAD is done in one continuous layout it would be nice to get rid of the Viewports and just print a full-size PDF of the entire site. For now, combining the PDFs might make some of your workflows a little easier.

I’m not sure how the industry is going to handle the Sign/Seal part of model submittals, but until then, signed PDF’s it is.

-

Points: 925Rank: UC2 Brainery White Belt IIII

@troydegroot thanks for sharing the video.

That is a work around for sure and exactly supports my point. I’m responsible for creating the cut sheets (which honestly is a pain and time consuming), that then someone would need to do those steps for. On most projects this needs to be done for multiple different plan types, having to do the “same thing” numerous times. We (designers) should just be creating the combined version in the first place. Taking a step back, maybe it starts with going with the familiar, standard sheet sizes, but including a master/index sheet that is larger and has hyperlinks to individual sheets if those are needed/wanted for other purposes.

In theory this leads to no cut sheets, just multiple different plan types, taking plan sets from hundreds of sheets to tens of sheets. Which in return becomes familiar and is the step into 3D pdfs and digital models.

-

-

Points: 32,179Rank: UC2 Brainery Advanced Brown Belt III

Great discussion topic @Jeff.Collins

Wearing my Project Engineer hard hat a full project PDF would be a wonderful tool! Especially if it was setup with clearly identified layers so that you can toggle off what you don’t need to see. If it was a nice straight job it would be great to plot out a single sheet that I could hang on the wall in the trailer without having to tape multiple sheets together.

Putting on my tie as an Owner’s Representative I cringe over the potential document control issues having “live” documents out there. A flattened, black and white document that can’t be edited is the contract in this world. Having sheet numbers to reference in correspondence, RFI responses and such are key to good documentation.

While some portions of the industry are going digital at every opportunity you are correct that most contractors want paper and a .PDF file that they can print/plot copies at will – and measure in Revu! While they get tattered and dirty you never have to worry about charging a set of paper plans in the field!

-

Points: 925Rank: UC2 Brainery White Belt IIII

Thanks for sharing @David Cutler

“…it was setup with clearly identified layers so that you can toggle off what you don’t need to see.” Agree with this, certainly related, teaching people pdf’s can have layers is also important and a step to reducing the plan types needed.

“If it was a nice straight job it would be great to plot out a single sheet that I could hang on the wall in the trailer without having to tape multiple sheets together.” Funny thing is designers do this during the early stages of design and then we chop it (additional time and money) to give it to contractors.

“Having sheet numbers to reference in correspondence, RFI responses and such are key to good documentation.” Could still have sheet numbers and we have alignments (in the world I’m use to) that could be referenced. Adding layers that can be manipulated would add a wringle, but maybe then there’s a “flat” contract plan and then a user friendly “smart” pdf.

-

-

Points: 32,179Rank: UC2 Brainery Advanced Brown Belt III

I thought of this discussion today @Jeff.Collins after I joined in a session of “Civil Chat”. As Jason Artley from Morning Coffee Revu put it I got my feathers ruffled over a discussion of how Civil Designers should distribute PDFs. The way I heard it the host was basically saying that ideally, due to liability issues and the potential for people to copy designs, PDFs should be distributed as scanned documents after they are sealed by a PE. This is a polar opposite to what you are suggesting with a full project PDF. I was suggesting that a “quality” PDF would have layers, bookmarks, labeled pages, etc. The response, again, as I heard it, was that basically Civil 3D should be used to prepare what amounts to a crayon sketch for distribution!

So, how does your company prepare documents for distribution?

-

Points: 32,179Rank: UC2 Brainery Advanced Brown Belt III

Still out their @Jeff.Collins ?

Bluebeam must have been reading this discussion @Jeff.Collins

At #UNBOUND25 last week they announce a “stitching tool” that I thought they said is included in Revu 21.7, but I can’t seem to find it yet. Perhaps it is still in the Beta test phase.

Anyway, it is similar to @Vince ‘s manual process, but maintains the layers and full PDF functionality (line weight dimming for example). I’m very excited to see how I can work this new feature into my workflows.

-

Points: 18,253Rank: UC2 Brainery Advanced Blue Belt III

Stitching is still in Beta and will probably only be available in MAX.

-

Points: 32,179Rank: UC2 Brainery Advanced Brown Belt III

Thank you for the clarification @Doug McLean

I guess I was too excited about the possibilities to be listening carefully… 🙃

-

-

Points: 27,996Rank: UC2 Brainery Advanced Brown Belt I

The Stitching button is located in the current interface; it’s a side panel that you need to activate. But before you get too excited, I don’t think the tool is ready, and there is no documentation anywhere showing how to use it yet. I very quickly tried to figure it out, but had to move to some other pressing work.

A developer reached out to me about 2 years ago, asking about my video and workflow. Providing him with an understanding of how I stitched the drawings together and why the industry needs that functionality was the kickstart of the Stitching tool. Can’t wait to see it in action.

-

Points: 18,253Rank: UC2 Brainery Advanced Blue Belt III

I’m not seeing it as a Side Panel.

I was in a webinar yesterday and the Host (Stephanie) had it in the Document Menu directly under the Compare and Overlay headings.

I would love to have to activated because I can see this being used in Architectural as well as Civil.I still have the version that we were using on the Beta (21.7.0) for the ‘Magic Wand’ features, but I’m not seeing Stitching anywhere.

-

Points: 15,786Rank: UC2 Brainery Advanced Blue Belt

I have the stitching feature available, but I get an error every time that I try to use it.

I also have the wand available – sometimes. When I say sometimes, I mean about 5% of the time which is very odd!

-

Points: 18,253Rank: UC2 Brainery Advanced Blue Belt III

I was using that wand yesterday on a re-tender I’m currently working on… what a time saver.

I’m glad that the team heard our calls and will be putting it on a Rt. click menu when its released.

-

Points: 32,179Rank: UC2 Brainery Advanced Brown Belt III

As it stands now @Doug McLean does the Magic Wand capture everything (formatting, custom column data, etc.) on the “copied” tool? I’m cautiously optimistic about this one… 🙂

-

Points: 18,253Rank: UC2 Brainery Advanced Blue Belt III

it does.

Its a really cool upgrade -

Points: 15,786Rank: UC2 Brainery Advanced Blue Belt

How are you getting the option to use the wand at the moment – mine does come up occasionally but not really when I want it.

-

Points: 18,253Rank: UC2 Brainery Advanced Blue Belt III

its still a keyboard only command, so you have to execute it.

They have told me that this was an overwhelming request from the Beta testers, so it will be going on a Rt. Click menu in 21.8

-

-

-

-

-

Points: 925Rank: UC2 Brainery White Belt IIII

I am still out here. Thank you for sharing. I’ll have to check it out.

I forgot I posted about this.

-

Points: 32,179Rank: UC2 Brainery Advanced Brown Belt III

Unfortunately @Jeff.Collins I may have overstated some of the functionality of the “Stitching” feature that is being added. Since my comment above I’ve heard that, at least in the Beta version, that the Stitching feature does not maintain the layers and such – basically it is just automating the process that has been discussed previously where snapshots of the PDF are joined together on the same sheet.

I’m hopeful that they layers and associated information will be added in future improvements…. 🙂

-

-

Log in to reply.