THP Concrete Construction Field Report, a guest post by Nicholas Heim, PE

This week I wanted to highlight another Bluebeam user within the design & construction industry actively changing the landscape through custom workflows. Today my guest post is by Nicholas Heim, PE a Project Engineer with THP Limited in the Cleveland Ohio area, and an active member of the Detroit Bluebeam User Group. Nicholas is going to tell us about the process they use for concrete construction field reports in Bluebeam Revu.

Nicholas writes:

THP Limited’s innovation groups are always looking for ways to drive gains in productivity and efficiency in our daily operations. Several Bluebeam workflows we have developed in-house save us significant amounts of time and effort, particularly in the field. The workflow I would like to share today is THP’s concrete construction field report. Before we get begin, let us touch on some background that will help to make sense of it.

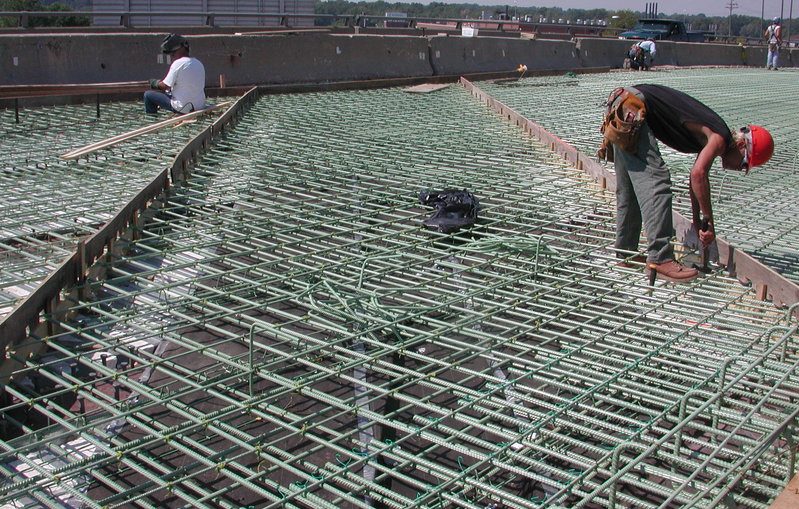

Our primary objective as any project’s structural engineer of record is to ensure that the structure is being constructed per the design intent – communicated through structural drawings and specifications. As such, we perform regular site visits to review the contractor’s progress. For concrete construction, these site visits happen shortly after all reinforcing is installed, typically the day before a pour. By reviewing the contractor’s work before the pour commences, we help to avoid issues that would otherwise be difficult to correct and help keep the project moving.

Prior to the development of this new workflow, our pre-pour site visit procedure was as follows:

- Conduct the review of the as-constructed reinforcing and detailing, comparing it to the appropriate documents that display the design intent.

- Dictate the discovered issues, if any, on hand-written carbon-copy paper.

- Detach the carbon-copy portion for the contractor, keeping the original for our records.

A few things that could be improved:

- The observations are purely written. The location of the issue is not explicit.

- The carbon-copy paper completely captures the thought process: scribbles, eraser marks, notes, etc. The final product does not look clean.

- The deliverable to the contractor and our record copy are physical and can be misplaced.

As part of our innovation groups, we welcome all employees to bring feedback to our meetings regarding what frustrates them about their day-to-day processes and procedures. On concrete design team did so and, based on their feedback, our innovation team boiled the solution down to the following:

- Many of the same issues occur from pour to pour. There needs to be a way to standardize the observations from project to project.

- For non-standard observations, there needs to be a way to allow the engineer to record the specific issue without being tied to an overly customized, time-consuming, or frustrating solution.

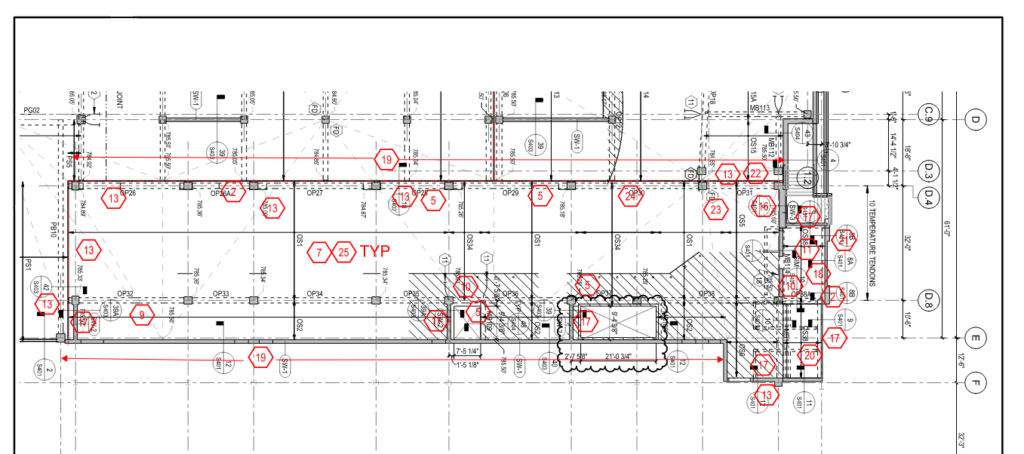

- The locations of the issues need to be clearly denoted on the plan. We need to show the contractor exactly where the issue was found.

- The distribution of the report needs to be fast – concrete is usually scheduled to be poured the next day and we need the contractor to be able to begin resolving issues before we leave the site.

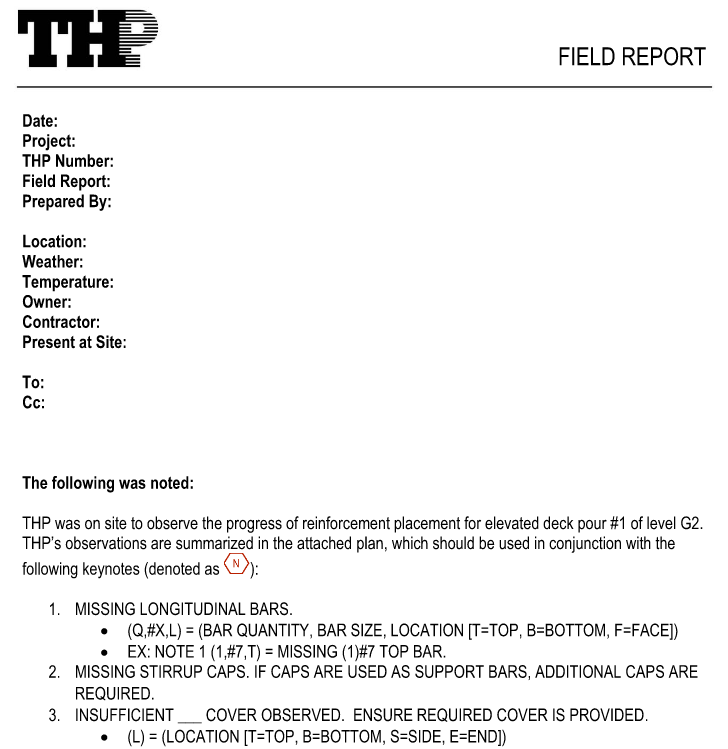

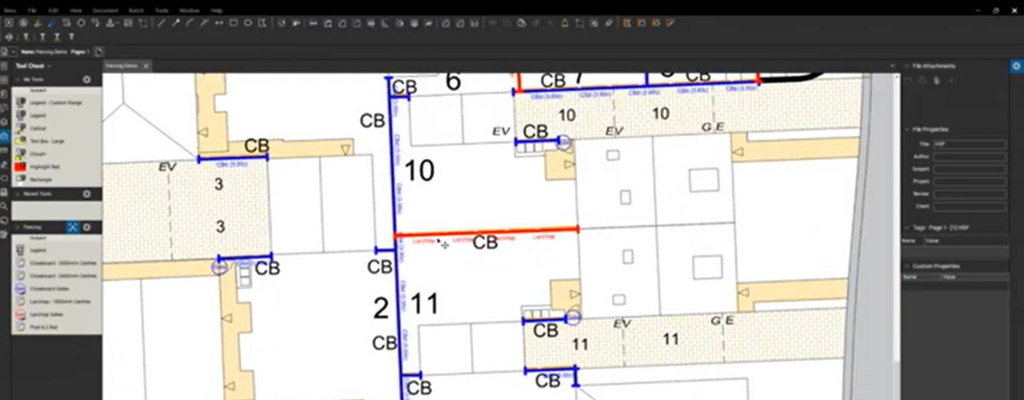

Understanding the above, we developed the THP Concrete Construction Field Report using Bluebeam Revu and Microsoft Word. The new workflow allows our engineers to streamline their reporting process with less ambiguity – the reported issues are clearly located on plan. This also allows our contractor partners to complete their “punch listing” more efficiently, helping them to keep the project on schedule. In short, the new workflow is:

- Prior to the site visit, our engineers take a screenshot of the portion of the structural plans where the upcoming pour is to occur and paste onto our custom THP Sketch Sheet.

- The engineer loads our concrete construction field report template (MS Word) and plan (Bluebeam) onto their OneDrive, updating it with project-specific information.

- After arriving on site, the engineer uses our custom keynoting toolboxes and touchscreen Microsoft Surface Book 2 to mark up the plan with keynotes corresponding to the standard or custom observations (dictated or types into the word file!), depending on what they find in the field.

- If the engineer feels that a condition requires photo documentation, they can take a photo of the condition and place it at the back of the field report.

- After the on-site review is complete, the engineer reviews their field report and plan prior to combining the two as a .pdf and sending to the contractor.

I hope you enjoyed Nicholas Heim’s description of THP Limiteds Concrete Construction Field Report workflow. With Bluebeam Revu so versatile and customizable, you’re really only limited by your own creativity to develop powerful workflows. If Revu is changing the way you do business, I’d love to help tell your story here on UChapter2. Even the shortest stories can spark ideas. Send me a direct message in the Brainery and we can work on it together.

You’ll also want to subscribe to my YouTube channel.

If you have any questions or tips you’d like to share with the global community, join the UC2 Brainery forum and work toward your Brainery Black Belt!

[…] great example of enhancement of an in-place workflow is the development of the concrete construction field report (check out the article for an in-depth description!). In summary, we took an existing workflow and […]